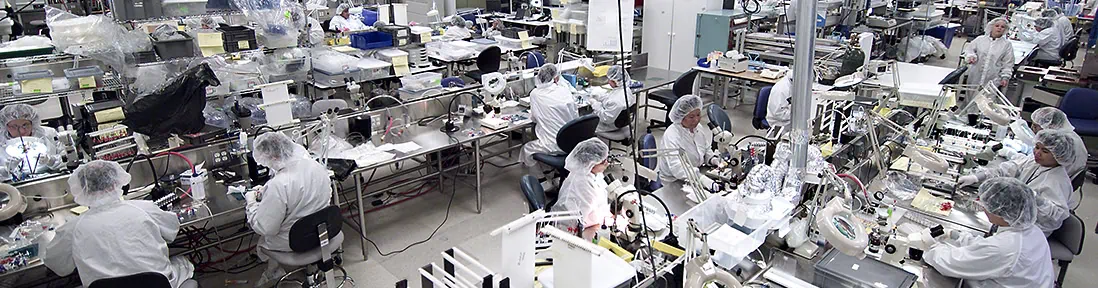

Eastprint, an East West Business has been an industry leader of printed electronics for more than 40 years. Throughout this time, we have consistently established and redefined the standards in creating high-tech, high-performance screen-printed electrodes (SPEs) and biosensors.

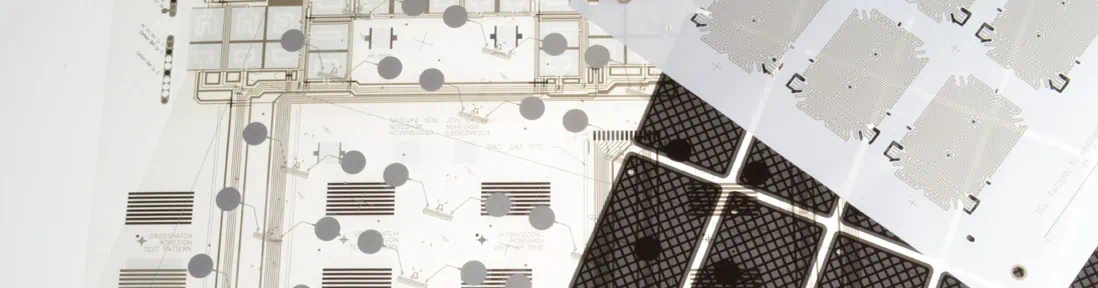

Screen-printed electrodes and biosensors are incredibly complex and require a range of advanced quality control procedures and processes to properly fabricate them. We offer a variety of conductive ink and fine line printing services, prototyping, engineering and design help, and more. Additionally, we use a particular set of conductive inks, such as silver, radiolucent, carbon, zinc, and dielectric, in our production.

WHAT ARE CONDUCTIVE INKS?

Simply put, conductive inks create printed products capable of conducting electricity. This is achieved through infusing silver flakes and other conductive metallic materials into the ink itself. While most metal materials maintain a solid state at normal temperatures, infusing liquid inks with flaked or powdered metallic nanoparticles facilitates electrical connections by creating conductive pathways once the ink is printed onto a substrate.

Conductive inks create electrical conductivity on surfaces in a broad variety of applications, and the list is expanding as the technology becomes better understood. A few examples include:

- Membrane Switches

- Medical Electrodes

- Capacitive touch film sensors

- Screen Printed Antenna’s

- In Mold Electronics

- E-Textiles

WHICH INKS ARE USED FOR OUR SCREEN-PRINTED ELECTRODES & BIOSENSORS?

At Eastprint, an East West Business, we use five primary types of conductive inks. These include:

SILVER CONDUCTIVE INKS

Silver conductive inks are often utilized in printed, flexible electronics. Silver has promising applications as a base for conductive inks and has supported the advancement of many technologies. The printed electronics market was once dominated by expensive materials such as gold and platinum, but silver-based conductive inks opened doors for cost reduction in a variety of fabrication processes.

RADIOLUCENT INKS

Radiolucent inks are permeable to one or more forms of radiation. This makes them ideal for facilitating critical functions in many medical devices, such as the electrodes used in EKG/EEG procedures or the pads used on AEDs and defibrillators.

CARBON INKS

Carbon inks are exceptionally lubricious, making them ideal for applications which require thermal stability and low friction. Their low reactivity to solvents and other chemicals makes them an ideal choice for applications where potentially damaging solutions are utilized.

ZINC INKS

Zinc-based conductive inks are utilized as electron transport layers in printed electronics. They allow processing temperatures as high as 80° C, which makes them excellent for electron extraction layers in solar cells, as well as other high-temperature conductive printing applications.

DIELECTRIC INKS

Dielectric inks play a critical role in the protection and enhancement of other conductive materials. These inks are created through blending existing conductive inks with a dielectric coating designed to create an insulation layer. Silver inks, for example, can be made more durable through the application of a dielectric coating. Dielectric inks see frequent use in the creation of flex circuits and membrane switches.

CONDUCTIVE INK APPLICATION SOLUTIONS FROM Eastprint, an East West Business

A variety of industries have begun to see the value of conductive inks for cost reduction in applications that use more expensive conductive metals. Forward-thinking organizations and industry leaders utilize this science every day to create new, beneficial technologies that change the landscape of technology.